Study and Characterization of EN AW 6181/6082-T6 and EN AC 42100-T6 Aluminum Alloy Welding of Structural Applications: Metal Ine

Significance of the superposition of cyclic mechanical and corrosive loadings in the qualification process of aluminium alloys - Bauer‐Troßmann - 2015 - Materialwissenschaft und Werkstofftechnik - Wiley Online Library

Study and Characterization of EN AW 6181/6082-T6 and EN AC 42100-T6 Aluminum Alloy Welding of Structural Applications: Metal Ine

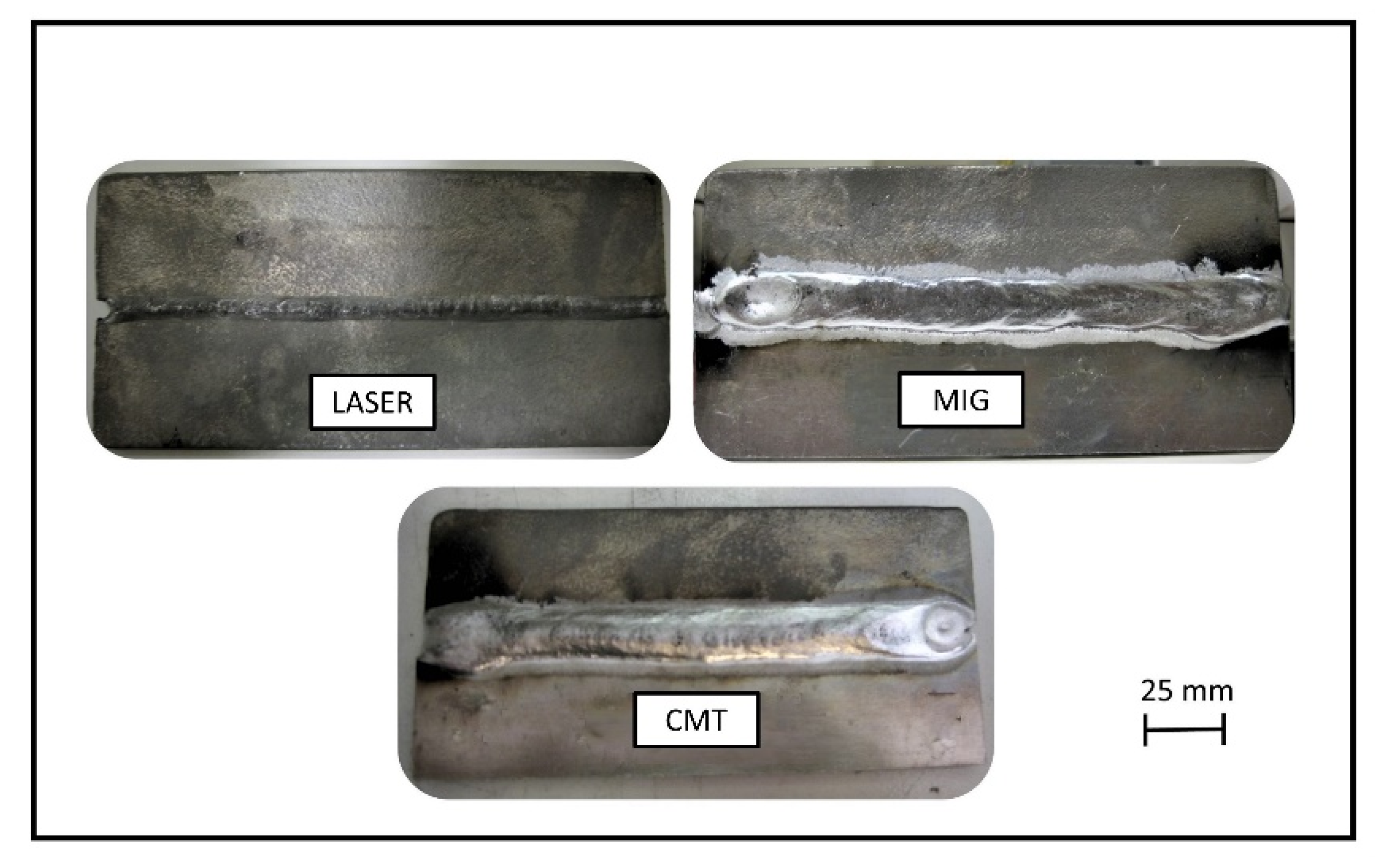

PDF) Study and Characterization of EN AW 6181/6082-T6 and EN AC 42100-T6 Aluminum Alloy Welding of Structural Applications: Metal Inert Gas (MIG), Cold Metal Transfer (CMT), and Fiber Laser-MIG Hybrid Comparison

Study and Characterization of EN AW 6181/6082-T6 and EN AC 42100-T6 Aluminum Alloy Welding of Structural Applications: Metal Ine

Study and Characterization of EN AW 6181/6082-T6 and EN AC 42100-T6 Aluminum Alloy Welding of Structural Applications: Metal Ine

PDF) Study and Characterization of EN AW 6181/6082-T6 and EN AC 42100-T6 Aluminum Alloy Welding of Structural Applications: Metal Inert Gas (MIG), Cold Metal Transfer (CMT), and Fiber Laser-MIG Hybrid Comparison

Metals | Free Full-Text | Study and Characterization of EN AW 6181/6082-T6 and EN AC 42100-T6 Aluminum Alloy Welding of Structural Applications: Metal Inert Gas (MIG), Cold Metal Transfer (CMT), and Fiber

Metals | Free Full-Text | Study and Characterization of EN AW 6181/6082-T6 and EN AC 42100-T6 Aluminum Alloy Welding of Structural Applications: Metal Inert Gas (MIG), Cold Metal Transfer (CMT), and Fiber

Study and Characterization of EN AW 6181/6082-T6 and EN AC 42100-T6 Aluminum Alloy Welding of Structural Applications: Metal Ine

![PDF] Quality Index of the AlSi7Mg0.3 Aluminium Casting Alloy Depending on the Heat Treatment Parameters PDF] Quality Index of the AlSi7Mg0.3 Aluminium Casting Alloy Depending on the Heat Treatment Parameters](https://www.researchgate.net/profile/Aldona-Garbacz-Klempka/publication/305222288/figure/tbl1/AS:614118604161028@1523428693170/46_Q320.jpg)

PDF] Quality Index of the AlSi7Mg0.3 Aluminium Casting Alloy Depending on the Heat Treatment Parameters

TAILORING PROPERTIES TO REPRESENT HPDC TENSILE AND FATIGUE BEHAVIOUR IN ALUMINIUM-SILICON CAST ALLOY PROTOTYPES

TAILORING PROPERTIES TO REPRESENT HPDC TENSILE AND FATIGUE BEHAVIOUR IN ALUMINIUM-SILICON CAST ALLOY PROTOTYPES

PDF) Study and Characterization of EN AW 6181/6082-T6 and EN AC 42100-T6 Aluminum Alloy Welding of Structural Applications: Metal Inert Gas (MIG), Cold Metal Transfer (CMT), and Fiber Laser-MIG Hybrid Comparison

![PDF] Quality Index of the AlSi7Mg0.3 Aluminium Casting Alloy Depending on the Heat Treatment Parameters PDF] Quality Index of the AlSi7Mg0.3 Aluminium Casting Alloy Depending on the Heat Treatment Parameters](https://i1.rgstatic.net/publication/305222288_Quality_Index_of_the_AlSi7Mg03_Aluminium_Casting_Alloy_Depending_on_the_Heat_Treatment_Parameters/links/57855e7808aef321de2a99d8/largepreview.png)